Recirculation Furnaces of Batch Heat Treatments

The Recirculation Furnaces of Batch Heat Treatments require tight temperature uniformity in large furnace space.

Features

- Heating System:

- Gas-fired convection furnaces (Directly or indirectly)

- Electrically heated convection furnaces

- Excellent temperature uniformity with accurate temperature control system

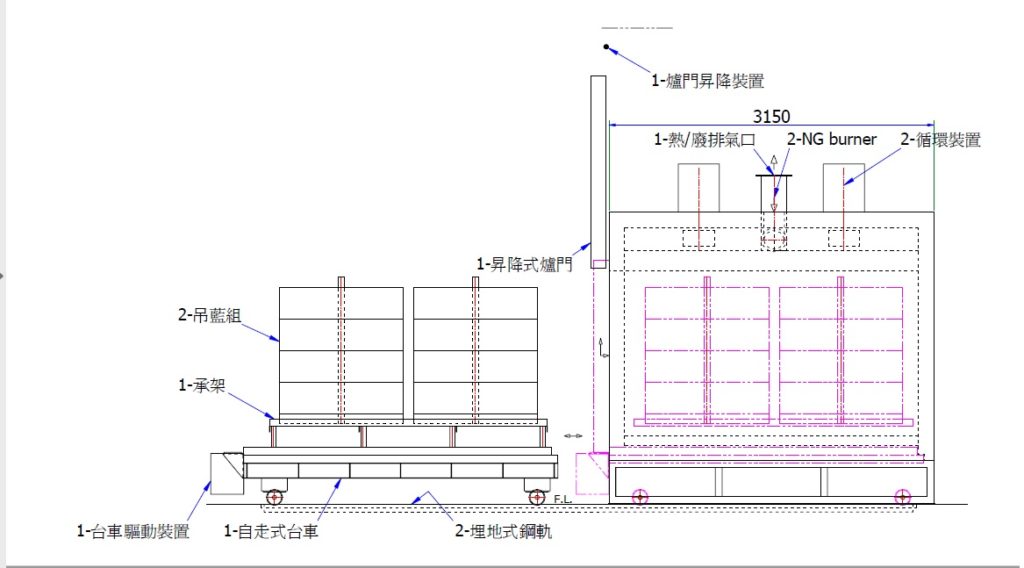

- Loading and unloading can be manual or automatically operated

- Door can be hinged or sliding type with manual or automatic door driving mechanisms

- Special design automatic door tightening system

- Forced internal recirculation in vertical, longitudinal or cross flow by mean of centrifugal fans

- Adjustable inlet and outlet to control desire convection direction

- Heating elements can be easy access from outside of furnace for maintenance

- Cooling process by ambient air recirculation system can be optionally supplied

Applications

- Heat treatments for

- Stress relieving (Aluminum, Titanium, etc)

- Tempering

- Dehydrogening

- Annealing and artificial aging (Aluminum)

- Curing (Ceramic composites and paints)

- Aimed at industrial sectors such as Aeronautics, Automotive, Heavy Machinery and Electric, Metalworking, Energy (Wind, Hydraulic, etc),

Specifications

- Maximum working temperature (≤750℃)

- Option Items: Transfer car

Automatic basket positioning systems

Automatic load feeding devices

Operation Sequence:

其它說明: